Product Description

This chuck is identical to P/N 1041 except for an electroless Nickel-Teflon coating that has been applied to help prevent wear and corrosion. This special coating has been applied to all external and internal surfaces of the chuck (except for chuck jaws), significantly improving the life of the chuck. This chuck also opens and closes more smoothly due to the lubrication properties of Nickel-Teflon.

- Ductile plating with columnar structure

- Harder than any other nickel-based coating

- Coating uniformity that eliminates post-plate grinding (or burnishing)

- Wear properties overall superior to hard chromium

- Hardness (68-72 Rc)

- Low coefficient of friction (.044) Teflon™ is .04

- Uniform coating thickness up to .004”

- Accepts dry film lubricants

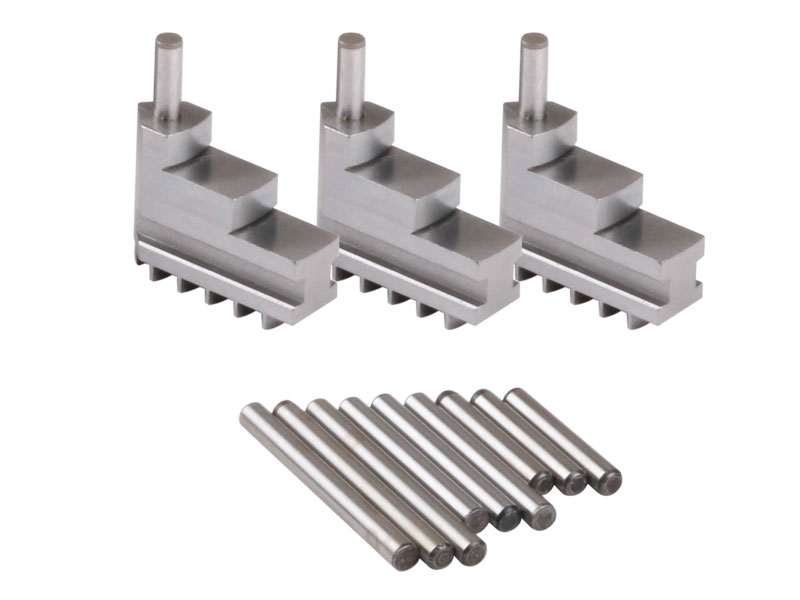

Jaw Options

- For those who have jobs where speed and ease of use are more important than maximum accuracy and want a chuck that is loose right from the start (No extra charge).

Add the note “loose jaws” to the comments box above - Soft (not hardened or machined) steel jaws are also available when you build your own chuck.

How to Distinguish between Standard Chucks and Coated Chucks

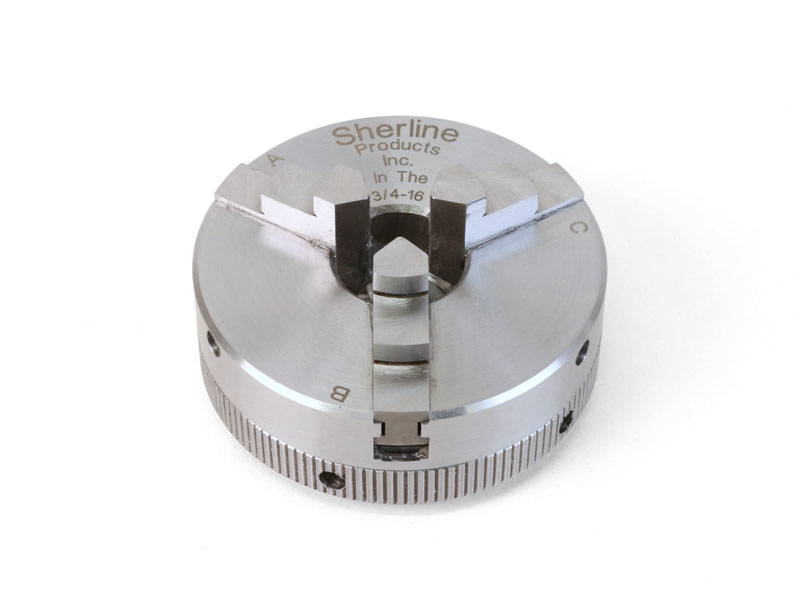

Some of our customers have been wondering how to tell the difference between our standard chucks and those that have the electroless Nickel-Teflon coating. Standard chucks have darker markings than the coated chucks (See Figure 1. Click on photo to view a larger image).

Figure 1—Examples: (Left) 1040 3-Jaw Chuck (3.1″), (Right) 1040C Electroless Nickel-Teflon Coated 3-Jaw Chuck (3.1″).

Here, at Sherline Products, each of our chucks is laser engraved with a company mark, chuck size, and jaw location. During the laser marking process the laser removes a bit of the surface and darkens the material below (Figure 1, left). When chucks are sent out to receive the Nickel-Teflon finish the coating process changes the dark engraved markings to a noticeably lighter finish (Figure 1, right).

There is also a subtle change in the color of the chuck, but in the absence of being able to compare them side by side, the most evident way to tell whether you have a coated chuck, or not, is to check the color of the laser markings.