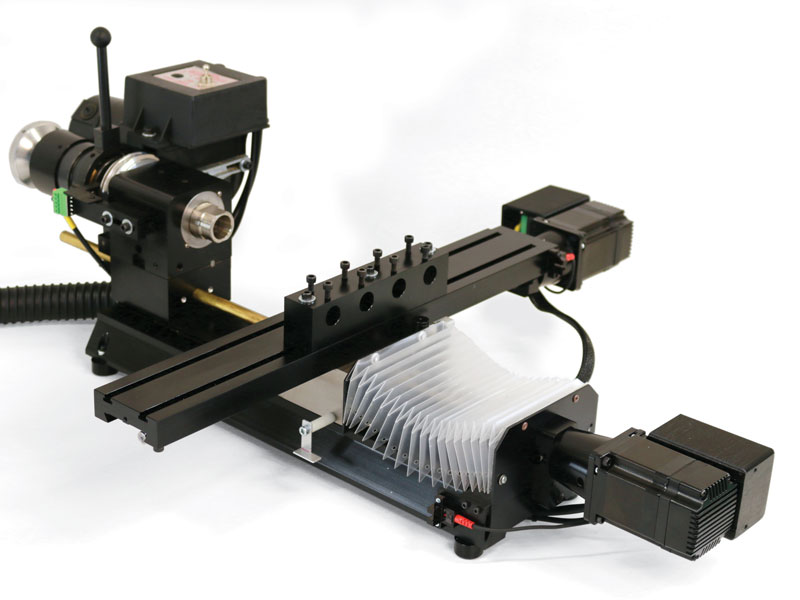

About the Accu-Pro Turn Chucker Lathe System with Ball Screws

We designed our Accu-Pro chucker lathe for our industrial customers who want the convenience of using multiple tools in a single setup. The chucker lathe has an 18″ aluminum base, an 18″ crosslide that accommodates the 3/8″, or 5/8″ gang-tooling tool posts, optional tool posts (tools not included), 36V closed-loop stepper motors with #23 NEMA frames, motor mounts with high-torque couplings, and C5 bearings in the headstock for smoother spindle operation.

This machine is perfect for the customer looking for a benchtop or tabletop machine for making small, precision parts. Our machines are made in the USA, and our customer service is second to none. We have sold many of these machines to medical and high-tech companies and have received great feedback. Although our machines are small, they are capable of producing the same high-quality precision parts that are made on a full-size machine.

Ball Leadscrew Specifications

- Rolled Ball Screw with BSH Nut

- 10mm Diameter, 2mm Lead

- C7 Accuracy*, P1 Preload

*C7 accuracy has a linear tolerance of 50 micrometers / 300mm or .002″ / 12.0″.

The ball screws are only available in metric.

About the Sherline/MASSO CNC G3 Touch Controller

The MASSO Touch Controller with power supply and spindle drive card lets you input data to the controller via a state-of-the-art touch screen. With MASSO, you can write your CNC programs on your computer (Windows, Mac, Linux, etc.) and then transfer your program to the controller via a USB flash drive. You no longer have to use a dedicated operating system like Linux or Mach 4 to control your machine.

The Touch Controller includes:

- Industrial cable system from the controller to the machine

- 36-volt power supply

- Touch-controller stand

Do you want to know more about the Sherline/MASSO G3 CNC controller? Here are some resource links for your reference.

- Sherline/MASSO G3 Help page

- MASSO G3 FAQs page

- MASSO G3 Videos page

The MASSO Accu-Pro Turn Chucker Lathe System Package includes:

- 18″ Chucker Lathe with ball screws

- A Sherline/MASSO G3 Touch Controller

- G-code Spindle Speed Control with threading capability

- An optical encoder

- WiFi is standard with the MASSO G3 Touch Controller

- Two 36-volt, Closed-Loop, High-Torque Stepper motors with a 70 in/min maximum feed rate

- Professional cable wraps and covers for the X- and Z-axis

- MASSO homing sensors on all axes

- USB 4 GB flash drive (With software, machine settings, sample programs, and PDF instructions included.)

- 1-year warranty on all machine components for non-production use. 90-day warranty on CNC and electronic controller-related components

Standard equipment for the Accu-Pro Turn Chucker Lathe includes:

- A powerful 90V DC motor with an electronic speed controller

- 18″ aluminum base

- Electroless nickel/Teflon-coated saddle

- 18.0″ (457 mm) x 2.75″ (70 mm) table with two T-slots

- Your choice of gang-tooling tool posts that hold up to four tools: 3/8″ (P/N 5930) or 5/8″ (P/N 5935)

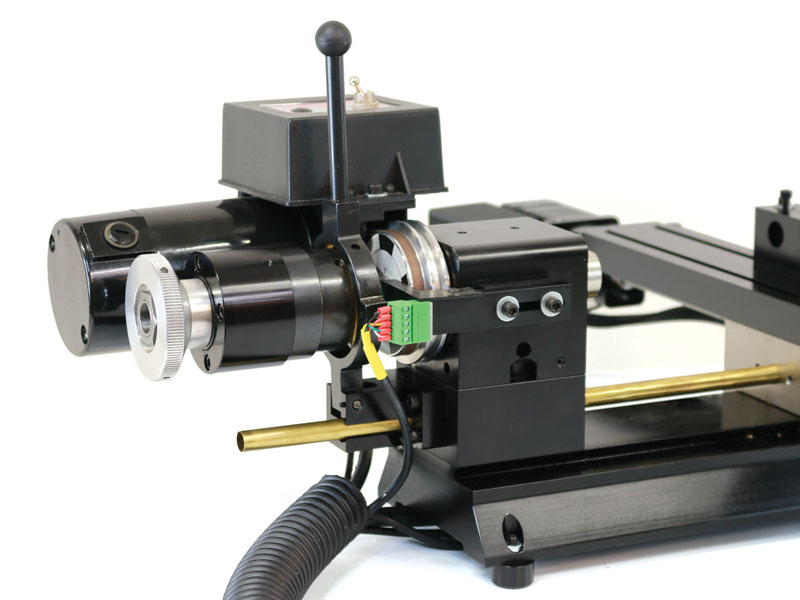

- Headstock with nickel-plated 3C spindle with precision C5 bearings, and with .001″ or less TIR* (*A TIR of .0005″ or less can be requested for an additional charge.)

- An Industrial 3C Lever Collet Closer

- The largest diameter through the collet is ½” (13mm). NOTE: collets are not available through Sherline Products. We recommend buying them from Hardinge.

- Stepper-motor mounts with high-torque couplings

- Oil reservoirs on the X/Z saddle to help keep critical parts lubricated

- Accordion way cover and brass-tube leadscrew cover that keeps chips off of the Z-axis leadscrew

Optional Accessories for the Accu-Pro Turn Chucker Lathe:

Click the Optional Accessories tab above to see which accessories are available for the Accu-Pro Turn Chucker Lathe.