About the Industrial Flanged Cartridge Spindles

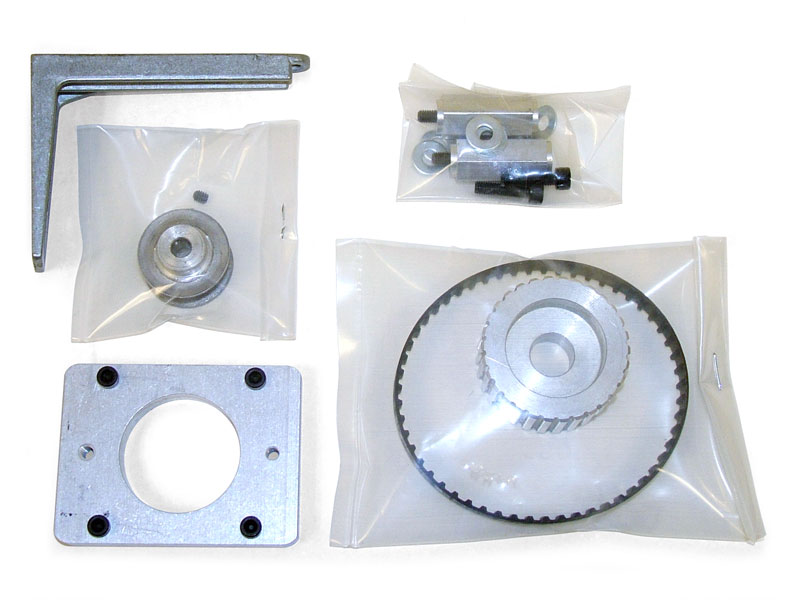

The cartridge spindle bodies are turned from bar stock steel and have a black oxide finish. The steel spindle shaft has a .405″ (10mm) hole through the center. They are available with your choice of a spindle (3/4-16 #1M taper or an ER-16*) and pulley configuration (a standard 2-step “V” belt pulley or a 30-tooth cog belt pulley).

All Sherline Industrial spindles feature lifetime lubricated bearings with adjustable preload. The bearings are Class 5 for better accuracy, tighter tolerance, smoother and quieter movement, and cooler running. The bearings in all our industrial headstocks, except for the 3C headstock, are 6004-VV C3P5 – ABEC 5. The headstock bearings are rated for a continuous speed up to approximately 4,000 RPM with factory preload adjustment of .0002″. You may need a slightly looser preload setting of .0003” for operating speeds up to 10,000 RPM.

*NOTE: We do not sell the collets used with the ER-16 spindle. Those are available through MSC Industrial Supply Co. or other tool supply sources.

Standard Features

- 3 mounting holes at 120° increments are 0.2″ diameter with a 0.325″ diameter countersink and are sized for 10-32 x 5/8″ socket head cap screws (supplied)

- Spindle bearing dust cover washer

- ER-16 collet nut ships with the ER-16 spindle headstocks

Installing the Flanged Cartridge Spindle

The Sherline flanged cartridge spindle has a 2.25″ diameter body and was designed to be mounted through a hole of 2.3″. It is attached using the three holes provided in the 3.1″ diameter flange. The holes are on a 2.676″ diameter bolt circle at 120° increments around the flanged diameter. The mounting holes are 0.2″ in diameter with a 0.325″ diameter countersink and are sized for 10-32 x 5/8″ socket head cap screws (supplied). The face of the spindle extends 1.0″ beyond the front surface of the flange.

Optional Nickel/Teflon Spindles

Most of our spindles are available with a Nickle/Teflon plating as a rustproof option for an additional cost. Check the option box above to add the Nickel/Teflon plating to your spindle order.

Spindle Precautions

These spindles should be considered light duty. A .405 (10 mm) through hole allows long stock to be passed through the spindle. This design provides a lot of versatility but was not intended for long or out-of-round parts to be rotated at high RPM. It is up to the operator to determine if the spindle and the setup are adequate and safe for the job being attempted.

The spindle is equipped with a dust cover, but it is not totally sealed. The presence of dust from grinding operations can shorten bearing life considerably. It was also not designed to be operated in a coolant bath. The spindle shaft should be shielded from coolant spray.