Product Description

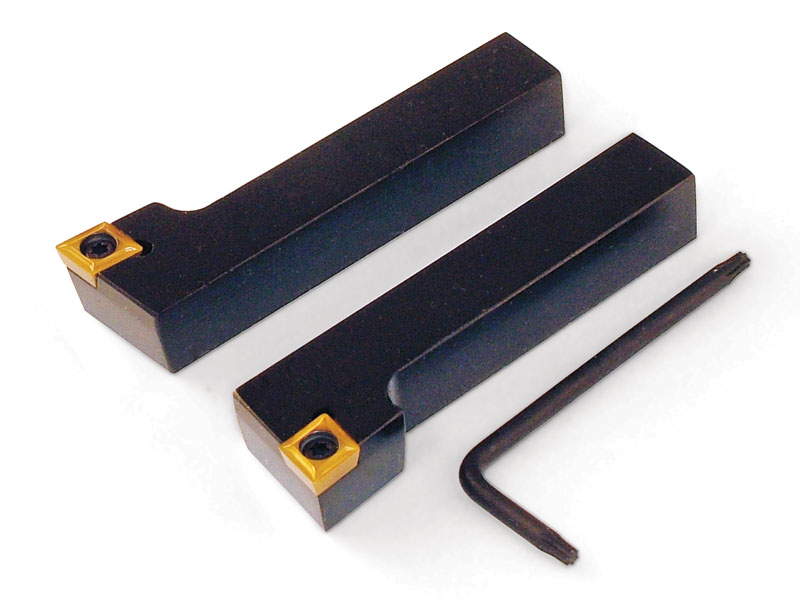

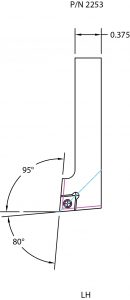

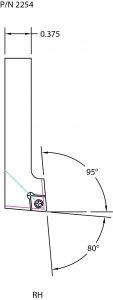

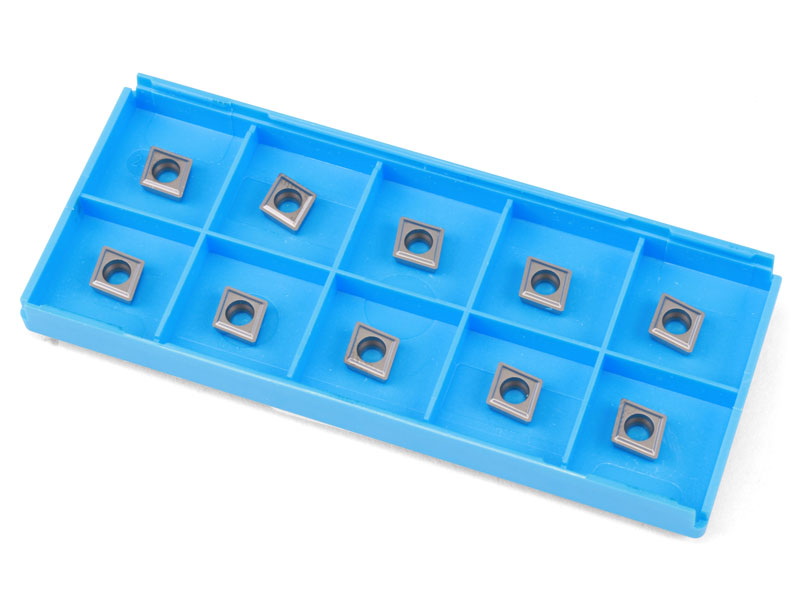

Sherline now manufactures its own inserted tip carbide tool holders. They are available with 80° inserts individually as a right-hand holder and a left-hand holder or as a pair. Each comes with an 80° carbide insert, hold-down screw and special Torx key. The 3/8″ square shank is held in a 3/8″ insert tool post. The 5° offset angle of the tip makes it easier to accomplish certain cuts. For example, by using the tool holder square with the crosslide, you can turn an O.D. up to a shoulder and then finish the shoulder by backing the tool out while still maintaining the proper tool clearance. The tip of the cutting tool is .375″ from the bottom of the holder, which is the industry standard. The holders are made from case hardened steel with a black oxide finish. The 80° inserts are generally used for roughing cuts. Holders with 55° inserts are also available.

Though relatively expensive, if a cutting edge becomes dull or chipped, the insert can be removed and rotated 180° to expose two new cutting surfaces, providing, in effect, two tools for the price of one.

The primary method of cutting metal on miniature machine tools is usually with high-speed steel tools as they are inexpensive, easily resharpened and can be ground into “form” tools for special jobs. However, inserted tip carbide tools can be lifesavers for some jobs. Though more expensive and not able to be resharpened, carbide tools hold their cutting edge when cutting exotic metals or abrasive materials and can speed up the cutting process. This is why they are used for most cutting tasks in the modern professional machine shop.

NOTE: A tool is named by the direction from which the chip leaves the tool; so a right-hand tool has its cutting edge on the left and the chip peels off to the right.