Product Description

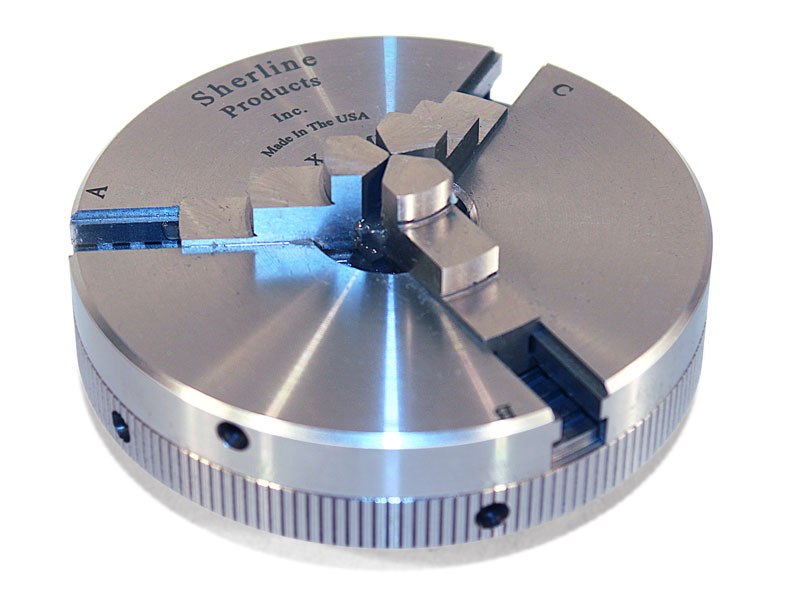

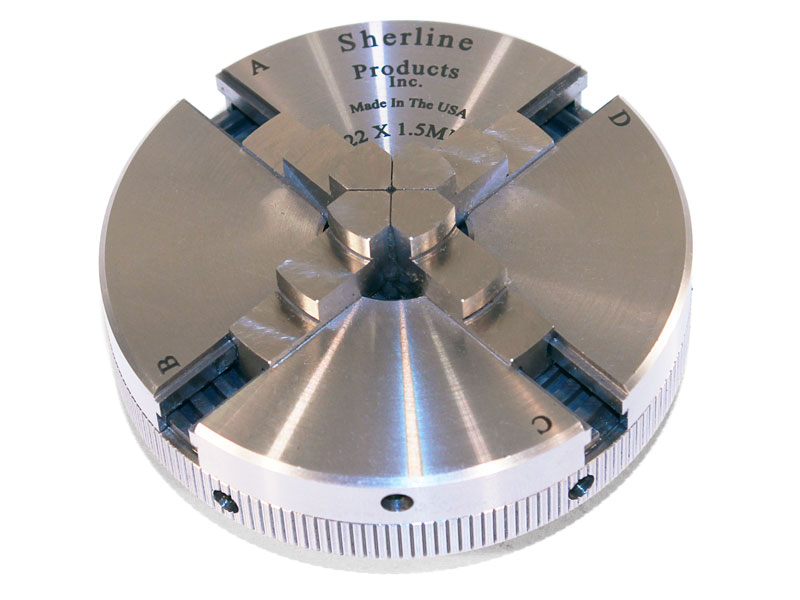

As with many of our accessories and machine modifications, our decision to make a 3C Collet Headstock was based on customers’ requests. Over the years, many of our customers have requested a spindle and collet that would allow larger diameter stock to go through the headstock. With the 3C collet, our customers can now hold stock up to 1/2″ diameter that will pass through the headstock.

When we designed our 3C Collet Headstock, we also designed it to be interchangeable with our standard headstock. The centerline height is the same. The mounting system is the same. Therefore you can easily switch from any of our other headstocks to the 3C headstock.

The 3C Spindle is electroless nickel plated to aid in rust prevention and increase the spindle’s surface hardness for durability.

We made the 1″ spindle wrench to go with the headstock to tighten and loosen the collets. The wrench is in a size range that will allow you to exert sufficient force without exerting excessive force. It is also in a size range that will make it easier to handle (than a standard 1″ wrench) when you are tightening and loosening the collet. Also included is a “Tommy” bar that you insert into one of the “Tommy” bar holes on the 3C headstock draw-bar knob. This is to aid in tightening and loosening the 3C collet.

If you wish to use a chuck with the 3C headstock, you can purchase the 3C to ¾-16 chuck arbor. All of our 3- and 4-aw chucks with a ¾-16 thread will fit on this arbor.

When it comes to making the 3C collets, we can’t compete with the cheap import collets, and companies like Hardinge already make quality 3C collets in many sizes. Therefore, we leave it up to you to decide who you want to buy your collets from.

NOTE: Certain attachments, like the Thread Cutting Attachment, the Lathe Power Feed, and the 10,000 RPM Pulley Set will NOT work on with the 3C Collet Headstock. If you are uncertain if an accessory will work with the 3C Collet Headstock, please call for more information.

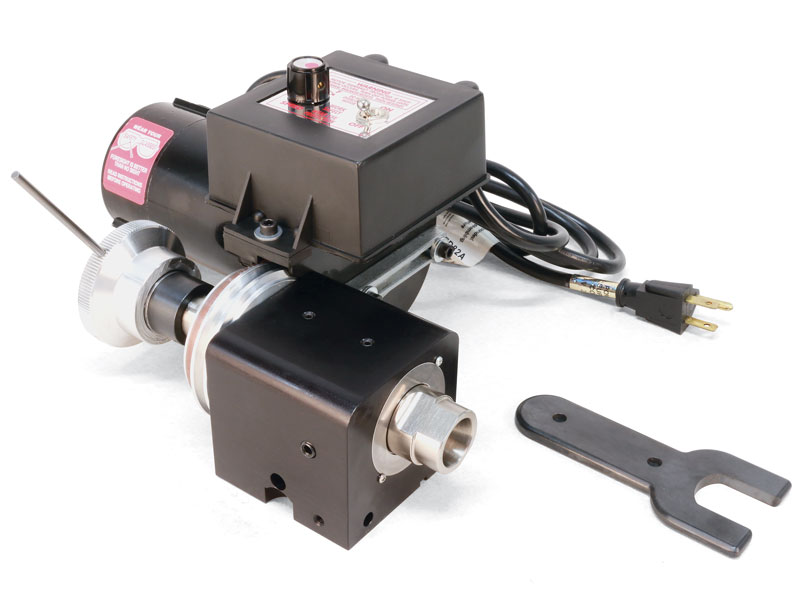

About the Motor

This unit can be purchased to replace an existing AC/DC motor on an older Sherline machine, to turn a mill XYZ base into a complete mill so that you don’t have to swap power units back and forth from the lathe, or as a stand-alone unit for custom tooling designs. This very compact, and well-engineered unit, costs far less than other DC units of similar power offered in major industrial tool supply catalogs.

For details on the motor and speed control, click on the Specifications tab above.