Product Description

Any Sherline lathe can be ordered ready for the application of stepper motors and Computer Numeric Control (CNC). Sherline installs stepper motor mounts in place of the leadscrew and crosslide handwheels. These mounts are designed to accept 23-frame size stepper motors. A dampened coupling for the 1/4″ motor shaft is included. The coupling drives the leadscrew through two 3/8″ bearings with adjustable preload to remove end play.

Once you have the machine, you will need to attach stepper motors and connect them through a driver to a computer. Several aftermarket companies provide the proper motors, drivers, and software to complete the package. You can read a list of these supplies and visit their websites for price comparisons by visiting the CNC Dealers page within Sherline’s site. Sherline also offers high-quality stepper motors, which can be found in the accessories section of this site.

Standard equipment for the lathe includes:

- A powerful 90V DC motor with electronic speed controller*

- 2.75″ (70mm) x 6.0″ (152mm) crosslide

- 24″ (610mm) steel bed that has 17″ (431mm) between centers

- 2.5″ (63mm) resettable “zero” handwheel for the leadscrew, one 2″ (51mm) resettable “zero” handwheel for the crosslide feed screw, and a 2″ (51mm) resettable “zero” handwheel on the tailstock. Each handwheel has laser engraved aluminum handwheel collars*

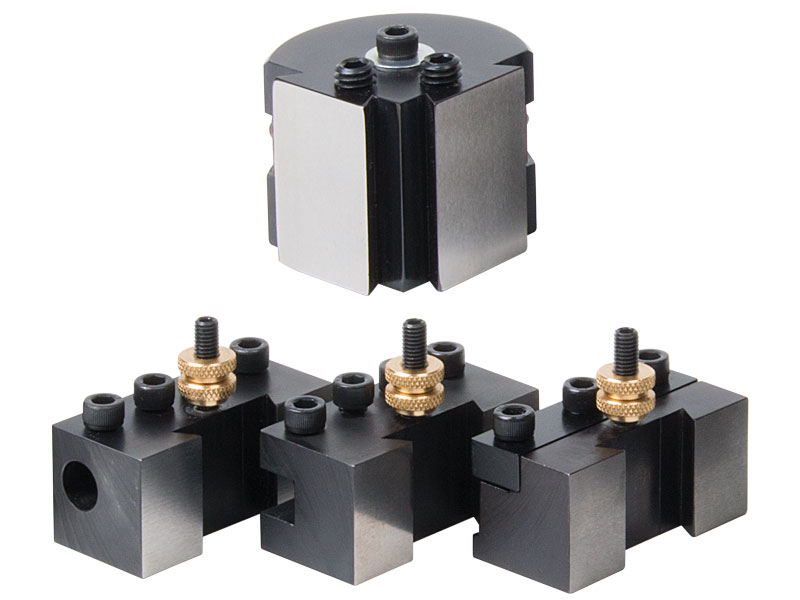

- Rocker tool post substituted for the standard tool post used on the short-bed lathes

- Pulleys, drive belt, faceplate, lathe dog, two dead centers, three hexagonal keys, tool post, sharpened high-speed steel cutting tool, eight-foot three-wire power cord, and instruction manual

* Not included with lathe without motor and speed control

**CNC-ready machines cannot be operated manually until stepper motors are installed.

Other ordering options:

Similar to the XYZ bases for our mills, you can now order the lathe without the headstock, motor, or speed control. Please see the selections in the drop-down menu above.