Product Description

Upgraded DRO Chip

Beginning August 1st, 2021, all DROs will ship with an upgraded chip. This new chip upgrade allows our Digital Readout to function with our ball screw machines as well as our standard leadscrew machines. We also programmed some upgrades based on customer feedback, like using Metric on Inch machines and using Inch on Metric machines.

The new DRO chip has six different modes to choose from based on the machine type, e.g., mill, lathe, leadscrew, or ball screw, and your preference of either inch or metric display on the DRO.

For more detailed information on setting up the modes for DRO, please see the DRO Mode Instructions.

NOTE: You must make sure you have the correct RPM tach sticker for your machine. Use a 6-pulse (P/N 81510) tach sticker if your machine is a leadscrew machine or a 5-pulse tach sticker (P/N P/N 87860) if your machine is a ball screw machine.

Any Sherline lathe can be ordered with a digital readout installed. Special handwheels with built-in encoders are installed in place of the standard handwheels on the crosslide and leadscrew. These handwheels are connected to a display box that translates handwheel rotation into a readout of table position to within .0005″ (or .01 mm). In addition, a constant readout of spindle RPM is displayed.

The advantage of a digital readout is that you no longer need to count handwheel rotations when moving distances longer than a single revolution. This helps eliminate math errors. The large, easy-to-read display reads out to 3 and a half decimal places to give accuracy to within .0005″. The display for each axis can be reset to zero at any time with the push of a button. Backlash values can be set for each axis in the programming so that backlash is electronically eliminated when changing the direction of handwheel rotation. A third axis is available on the display box should you later decide to add a vertical milling column or use it on a Sherline 3-axis mill. The readout can function with inch or metric lathes. In the metric mode, the position reads out to 1/100 of a millimeter.

- A powerful 90V DC motor with electronic speed controller*

- 2.75″ (70mm) x 6.0″ (152mm) crosslide

- 24″ (610mm) steel bed that has 17″ (431mm) between centers

- Special handwheels are supplied with DRO machines. These handwheels can be reset to zero electronically with the push of a button on the DRO display box. Sherline DRO lathes are outfitted with the special DRO 2″ (51mm) handwheels on the leadscrew and crosslide feed screw, and a 2″ (51mm) resettable “zero” handwheel on the tailstock. Each handwheel has laser engraved aluminum handwheel collars

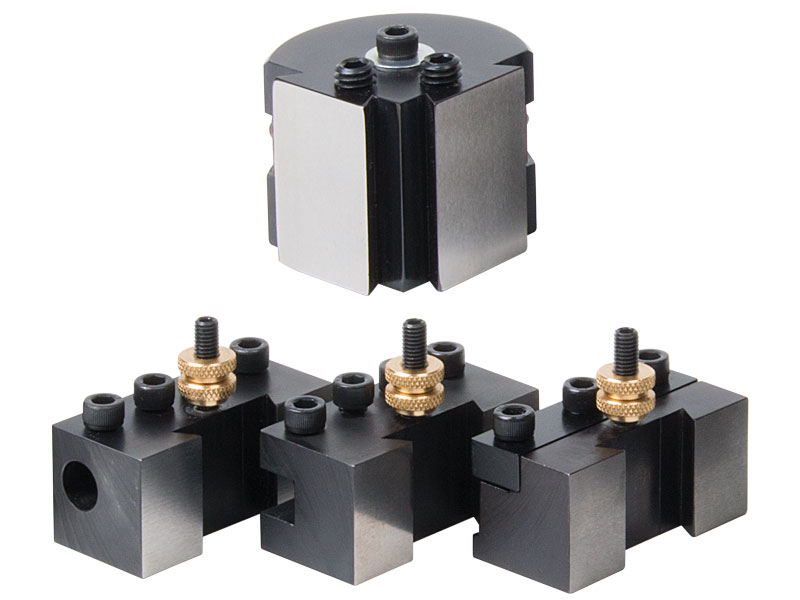

- Rocker tool post substituted for the standard tool post used on the short bed lathes

- Pulleys, drive belt, faceplate, lathe dog, two dead centers, three hexagonal keys, tool post, sharpened high-speed steel cutting tool, eight-foot three-wire power cord, and instruction manual

* Not included with lathe without motor and speed control

NOTE: The unit does not translate dimensions from inch to metric. It must be initialized to work with the pitch of the leadscrew to which the handwheel is attached.

The A Package Includes:

- 3.1″ 3-jaw self-centering chuck

- 3/8″ tailstock drill chuck w/ key, #0 Morse arbor, #1 Morse arbor with drawbolt

Other ordering options:

Similar to the XYZ bases for our mills, you can now order the lathe without the headstock, motor, or speed control. Please see the selections in the drop-down menu above.