Product Description

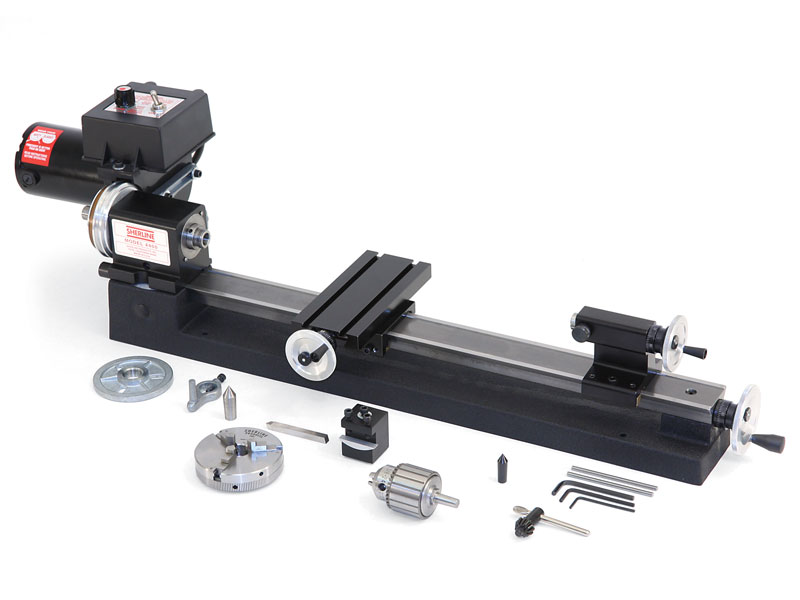

This lathe has 17″ between centers. The electronic speed control allows continuously variable speed control from 70 to 2800 RPM without belt changes. There is a second pulley position available that offers extra torque at low RPM if needed.

Many machinists find that the extra space between centers comes in handy when working with a part held in a chuck and a larger tailstock chuck with a long drill bit in place. The combination of chucks, part and drill can eat up a lot of the available center-to-center distance, and a little extra capacity is often appreciated. This lathe offers the same diameter turning capacities as the shorter lathe and same powerful motor/speed control. The differences are both the extra 9″ of center distance and the addition of extras like the adjustable zero handwheels and rocker toolpost, making this lathe a good value for the extra cost.

Standard equipment for the lathe includes:

- A powerful 90V DC motor with electronic speed controller*

- 2.75″ (70mm) x 6.0″ (152mm) crosslide

- 24″ (610mm) steel bed that has 17″ (431mm) between centers

- 2.5″ (63mm) resettable “zero” handwheel on the leadscrew, a 2″ (51mm) resettable “zero” handwheel on the crosslide feed screw, and a 2″ (51mm) resettable “zero” handwheel on the tailstock. Each handwheel has laser engraved aluminum handwheel collars

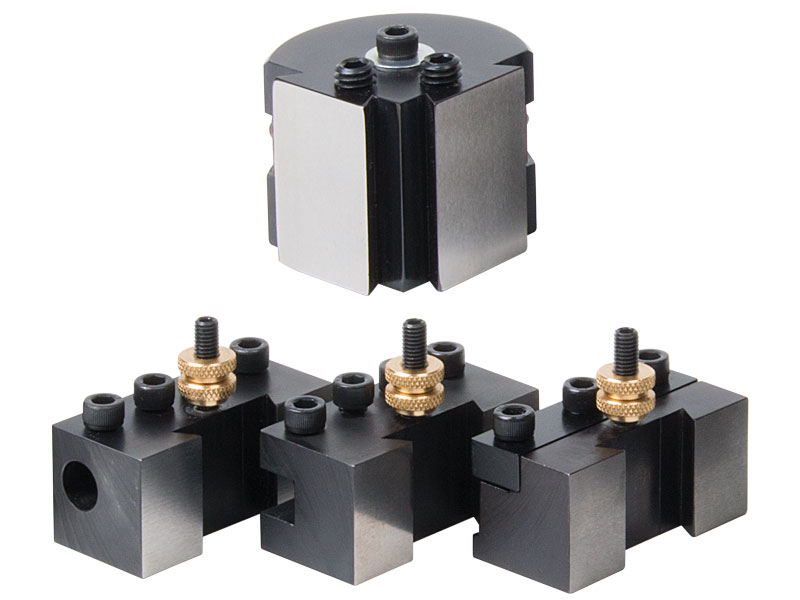

- Rocker tool post substituted for the standard tool post used on the shortbed lathes

- Pulleys, drive belt, faceplate, lathe dog, two dead centers, three hexagonal keys, tool post, sharpened high-speed steel cutting tool, eight-foot three-wire power cord, and instruction manual

* Not included with lathe without motor and speed control

The A Package Includes:

- 3.1″ 3-jaw self-centering chuck

- 3/8″ tailstock drill chuck w/ key, #0 Morse arbor, #1 Morse arbor with drawbolt

Other ordering options:

Similar to the XYZ bases for our mills, you can now order the lathe without the headstock, motor, or speed control. Please see the selections in the drop-down menu above.