Product Description

Sherline’s Ultimate CNC Machine Shop comes complete with a CNC-ready lathe and vertical milling machine, plus the stepper motors, computer, software, and cables to run them.

The 8-Direction Ultimate CNC Machine Shop system includes the following:

- Deluxe 3.5″ x 17″ Benchtop Lathe with two stepper motors, in either inch or metric measurements

- 14″ 8-Direction Benchtop Vertical Mill with three stepper motors, in either inch or metric measurements

- Handwheels on the rear shaft of the stepper motors also allow manual control

- Rotary table with stepper motor (for use as a 4th axis on the mill) and the computer

- A computer with Ubuntu Linux-based OS with linuxcnc 4-axis CNC software preinstalled

- Keyboard and mouse

- 4-axis driver board and power supply installed inside the computer to run either the mill or lathe, one at a time

- Computer cables to the X-, Y-, and Z-axes are 69″ in length

- Instruction and utility CD. The CD includes complete instructions and several free utilities to translate CAD files or TrueType fonts into G-code.

- A blank 4GB USB flash drive is also included

- 1-year warranty on all components for non-production use. 90-day warranty on CNC and computer-related components.

You supply only a monitor.

NOTE: Depending upon availability, the actual computer supplied with the system may look different than shown above.

In addition to the lathe, mill, and computer you get the following accessories:

17″ BENCHTOP LATHE

- 3.1″ 3-jaw Self-centering Chuck

- 3/8″ Drill Chuck w/ Arbors, Key and Drawbolt

- Steady Rest

- Live Center

- Rear Mount Cutoff Tool and Holder

- 3-pc. 1/4″ HSS Tool Set (LH, RH, Boring)

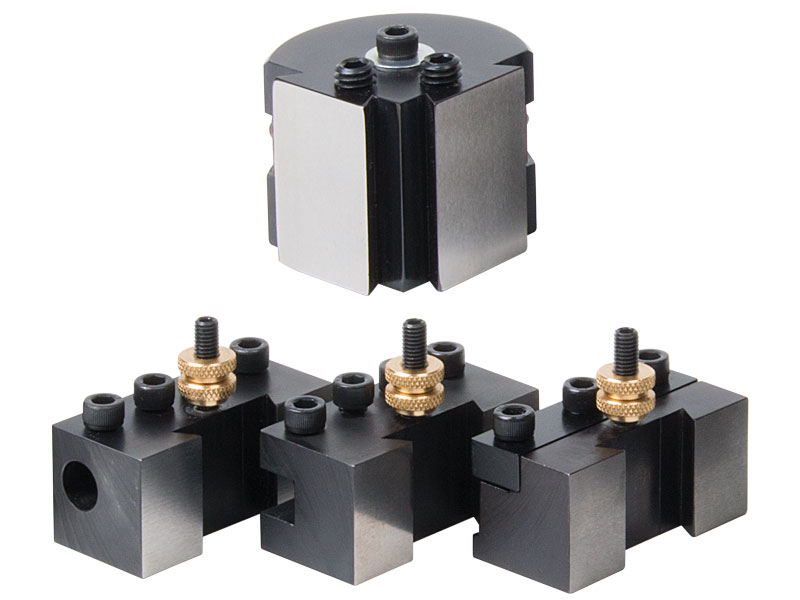

14″ 8-DIRECTION BENCHTOP MILL

- Headstock Spacer Block

- 3 pc. Center Drill Set

- Fly Cutter w/ 1/4″ Carbide Cutting Tool

- Boring Head

- Boring Tool (5/16″ min. hole, 1″ max. depth)

- 3-pc. Mill Collet Set w/ Drawbolt

- 1/4″ Drill Chuck w/ #1 Morse Arbor, Key and Drawbolt

- 3/8″ End Mill Holder

- 6-pc. 3/8″ Shank End Mill Set

- Milling Vise

- Step Block Hold-down Set

- 4″ CNC Rotary Table with Stepper Motor

- Tilting Angle Table

MISCELLANEOUS

- 5/32″ Sherline Hex T-Driver

- Sherline Accessories Shop Guide

- Safety Glasses

Sherline CNC Specification Links

|

The improper use of machine tools and their accessories can result in serious injury. Before using this tool, thoroughly read the instructions and make sure you understand its proper and safe use.

|

Always wear safety glasses when operating machine tools.

|

Download PDF Assembly and Instruction Guide

Download PDF DRO Instructions

Max clearance

(table to spindle) |

9.00″ (229 mm) |

Throat

(no spacer) |

Adjustable |

Throat

(w/ headstock spacer) |

Adjustable |

| Travel, “X” Axis |

8.65″ (220 mm) |

| Travel, “Y” Axis |

7.00″ (178 mm) |

| Travel, “Z” Axis |

5.38″ (137 mm) |

| Hole through spindle |

.405″ (10 mm) |

| Spindle nose thread |

3/4″-16 T.P.I. |

| Spindle nose taper |

#1 Morse |

| Spindle runout of Morse taper |

.0005″ or less |

| Handwheel graduations |

.001″ (.01 mm) |

| Electronically controlled spindle speed range |

70 to 2800 RPM |

| Width Overall* |

15.00″ (381 mm) |

| Depth Overall* |

Base footprint: 16.25″ (413 mm); With fully extended brass leadscrew cover: 20.625″ (524 mm) |

| Height Overall (Max.)* |

23.38″ (568 mm) |

| Table size |

2.75″ x 13.00″ (70 x 330 mm) |

| Hold-down provision |

2 T-Slots |

| Shipping Weight |

45 lb. (20.1 kg) |

Movements in addition

to X-, Y- and Z-axes |

Headstock rotation (90° left/right) |

| Column rotation |

(90° left/right) |

| Column pivot |

(90° forward/back) |

| Column swing |

(90° left/right) |

| Column travel |

(in/out) 5.5″ (140 mm) |

| Motor |

90 volt DC with electronic speed control that accepts any incoming current from 100VAC to 240 VAC, 50 Hz or 60 Hz.

Click here for motor specifications |

| Spindle Speed Range |

70-2800 RPM continuously variable by electronic speed control |

*Overall dimensions include motor and speed control

| Swing Over Bed |

3.50″ (90 mm) |

| Swing Over Carriage |

1.75″ (45 mm) |

| Distance Between Centers |

17.00″ (430 mm) |

| Hole Through Spindle |

.405″ (10 mm) |

| Spindle Nose Thread |

3/4″-16 T.P.I. |

| Spindle Nose Taper |

#1 Morse |

| Spindle Runout of Morse Taper |

.0005″ or less |

| Travel of Crosslide |

4.25″ (110 mm) |

| Tailstock Spindle Taper |

#0 Morse |

| Protractor Graduations |

0° to 45° by 5° |

| Handwheel Graduations |

.001″ (.01 mm) |

| Length Overall |

32.5″ (826 mm) |

| Width Overall |

8.00″ (267 mm) |

| Height Overall |

8.00″ (216 mm) |

| Shipping Weight |

31 lb. (14.1 kg) |

| Motor |

90 volt DC with electronic speed control that accepts any incoming current from 100VAC to 240 VAC, 50 Hz or 60 Hz.

Click here for motor specifications |

| Spindle Speed Range |

70-2800 RPM continuously variable by electronic speed control |

Max clearance

(table to spindle) |

9.00″ (229 mm) |

Throat

(no spacer) |

Adjustable |

Throat

(w/ headstock spacer) |

Adjustable |

| Travel, “X” Axis |

8.65″ (220 mm) |

| Travel, “Y” Axis |

7.00″ (178 mm) |

| Travel, “Z” Axis |

5.38″ (137 mm) |

| Hole through spindle |

.405″ (10 mm) |

| Spindle nose thread |

3/4″-16 T.P.I. |

| Spindle nose taper |

#1 Morse |

| Spindle runout of Morse taper |

.0005″ or less |

| Handwheel graduations |

.001″ (.01 mm) |

| Electronically controlled spindle speed range |

70 to 2800 RPM |

| Width Overall* |

15.00″ (381 mm) |

| Depth Overall* |

Base footprint: 16.25″ (413 mm); With fully extended brass leadscrew cover: 20.625″ (524 mm) |

| Height Overall (Max.)* |

23.38″ (568 mm) |

| Table size |

2.75″ x 13.00″ (70 x 330 mm) |

| Hold-down provision |

2 T-Slots |

| Shipping Weight |

45 lb. (20.1 kg) |

Movements in addition

to X-, Y- and Z-axes |

Headstock rotation (90° left/right) |

| Column rotation |

(90° left/right) |

| Column pivot |

(90° forward/back) |

| Column swing |

(90° left/right) |

| Column travel |

(in/out) 5.5″ (140 mm) |

| Motor |

90 volt DC with electronic speed control that accepts any incoming current from 100VAC to 240 VAC, 50 Hz or 60 Hz.

Click here for motor specifications |

| Spindle Speed Range |

70-2800 RPM continuously variable by electronic speed control |

*Overall dimensions include motor and speed control

Click on the link for the exploded view of the 8440-Series CNC Lathe to help identify replacement parts.

Click on the link for the exploded view of the 8020/8021 CNC Deluxe Mill to help identify replacement parts.

If you are still uncertain please call our customer service representatives for help with this item.